NOTICIAS

Conocimiento de acero inoxidable dúplex

Explicación detallada del acero inoxidable dúplex

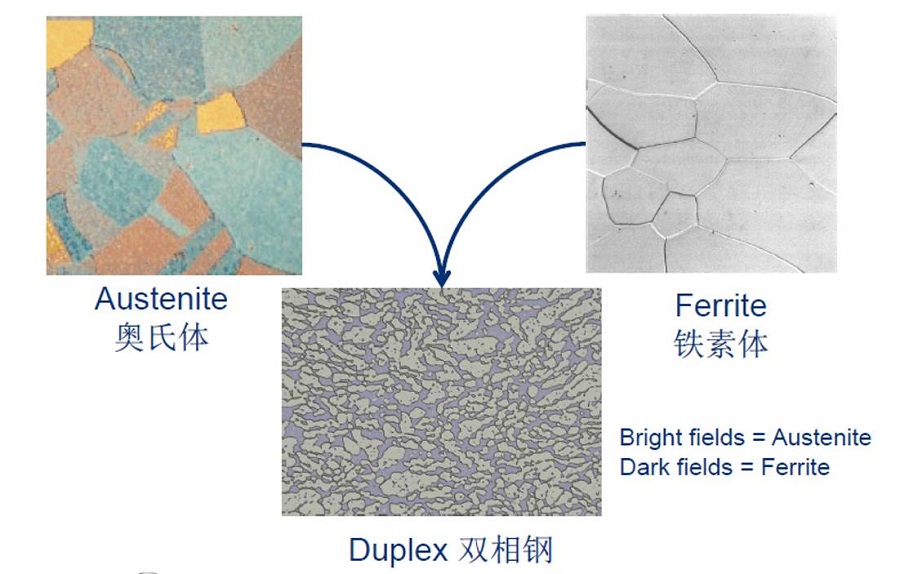

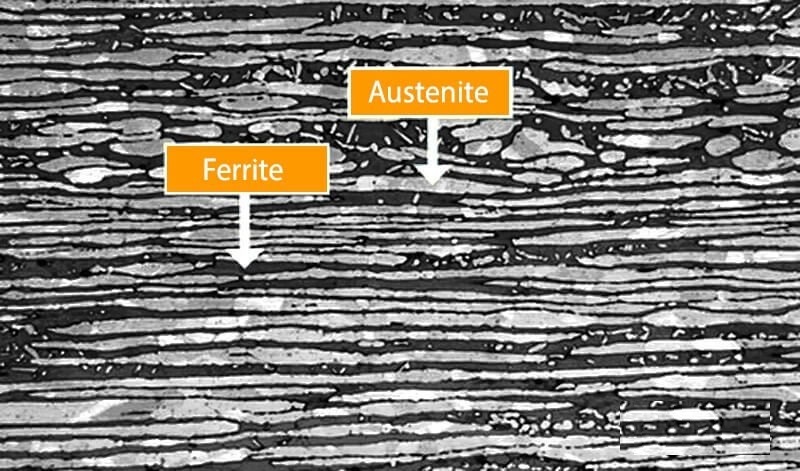

El acero inoxidable dúplex (DSS), con el símbolo químico S, se refiere a un tipo de acero inoxidable donde las fases de ferrita y austenita constituyen cada una aproximadamente el 50% del material. Generalmente, la fase menor debe representar al menos el 30% del acero inoxidable. En condiciones de bajo contenido de carbono, el cromo (Cr) oscila entre el 18% y el 28%, mientras que el níquel (Ni) oscila entre el 3% y el 10%. Algunos aceros también contienen elementos de aleación como molibdeno (Mo), cobre (Cu), niobio (Nb), titanio (Ti) y nitrógeno (N).

1. ¿Por qué no se oxida el acero inoxidable?

La resistencia a la corrosión del acero inoxidable generalmente aumenta con el aumento del contenido de cromo. Cuando el contenido de cromo en el acero supera el 12%, se forma una película de óxido muy fina pero densa (comúnmente conocida como película de pasivación) en la superficie del acero. Esta película protege el metal base de una mayor oxidación o corrosión, proporcionando así al acero inoxidable una excelente resistencia a la corrosión.

2. Composición del acero inoxidable dúplex

El acero inoxidable dúplex (DSS), como se mencionó anteriormente, comprende aproximadamente un 50 % de fases de ferrita y un 50 % de austenita. El contenido de cromo oscila entre el 18% y el 28%, el contenido de níquel entre el 3% y el 10% y puede contener otros elementos de aleación como molibdeno, cobre, niobio, titanio y nitrógeno.

Acero inoxidable dúplex

3. Clasificación del acero inoxidable dúplex

Existen varias categorías de acero inoxidable dúplex:

- Tipo de baja aleación: Representados por UNS S32304 (23Cr-4Ni-0.1N), estos aceros no contienen molibdeno y tienen un valor PREN de 24-25, lo que los convierte en reemplazos adecuados para AISI 304 o 316 en aplicaciones de corrosión bajo tensión.

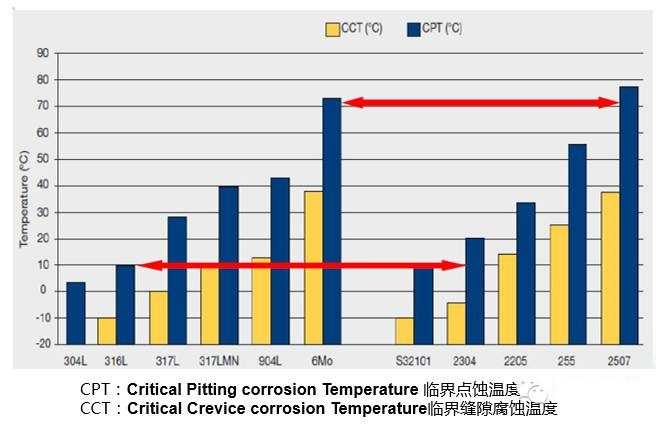

- Tipo de aleación media: Representado por UNS S31803 (22Cr-5Ni-3Mo-0.15N), con un valor PREN de 32-33, estos aceros exhiben una resistencia a la corrosión entre AISI 316L y aceros inoxidables austeníticos 6%Mo+N.

- Tipo de alta aleación: que normalmente contiene 25% de Cr, junto con molibdeno, nitrógeno y, a veces, cobre y tungsteno, los grados estándar como UNS S32550 (25Cr-6Ni-3Mo-2Cu-0.2N) tienen un valor PREN de 38-39. ofreciendo una resistencia a la corrosión superior en comparación con los aceros inoxidables dúplex con 22% Cr.

- Tipo de acero inoxidable súper dúplex: con alto contenido de molibdeno y nitrógeno, grado estándar UNS S32750 (25Cr-7Ni-3.7Mo-0.3N) y, a veces, tungsteno y cobre, con un valor PREN superior a 40, estos aceros son adecuados para entornos hostiles. , exhibiendo excelentes propiedades mecánicas y de corrosión comparables a las de los aceros inoxidables súper austeníticos.

4. Acero inoxidable dúplex frente a acero inoxidable austenítico y ferrítico

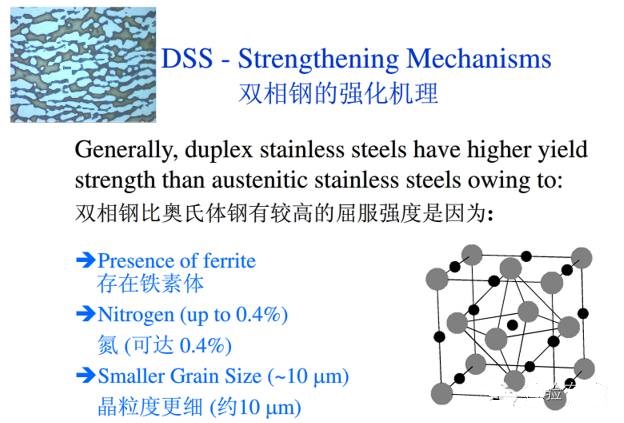

Debido a su estructura de dos fases, el acero inoxidable dúplex combina las ventajas de los aceros inoxidables austeníticos y ferríticos. Comparado con el acero inoxidable austenítico, el acero inoxidable dúplex ofrece las siguientes ventajas:

- Alto límite elástico: Más del doble que el acero inoxidable austenítico común, con suficiente ductilidad para las necesidades de conformado. El uso de acero inoxidable dúplex para la fabricación de tanques o recipientes a presión puede reducir el espesor de la pared entre un 30% y un 50%, reduciendo así los costos.

- Excelente resistencia al agrietamiento por corrosión bajo tensión: incluso los aceros inoxidables dúplex con el menor contenido de aleación exhiben una mayor resistencia al agrietamiento por corrosión bajo tensión que los aceros inoxidables austeníticos, especialmente en entornos de iones de cloruro, lo que aborda un problema importante en los aceros inoxidables austeníticos.

- Mayor resistencia a la corrosión: en muchos medios, la resistencia a la corrosión del acero inoxidable dúplex 2205 común es superior a la del acero inoxidable austenítico 316L típico, y el acero inoxidable súper dúplex exhibe una resistencia a la corrosión extremadamente alta, superando incluso a los aceros inoxidables austeníticos de alta aleación y a la corrosión. -aleaciones resistentes en algunos medios.

- Buena resistencia a la corrosión localizada: en comparación con los aceros inoxidables austeníticos con un contenido de aleación similar, el acero inoxidable dúplex tiene una mejor resistencia a la corrosión por desgaste y a la corrosión por fatiga.

- Coeficiente de expansión lineal bajo: más cercano al acero al carbono, lo que lo hace adecuado para la conexión con acero al carbono, lo que tiene importantes implicaciones de ingeniería, como en la producción de placas o revestimientos compuestos.

- Mayor capacidad de absorción de energía: en condiciones de carga dinámica o estática, el acero inoxidable dúplex tiene una mayor capacidad de absorción de energía que el acero inoxidable austenítico, lo que lo hace ventajoso para que los componentes estructurales resistan accidentes repentinos como colisiones o explosiones.

Sin embargo, el acero inoxidable dúplex tiene sus debilidades en comparación con el acero inoxidable austenítico y el acero inoxidable ferrítico:

- Aplicabilidad limitada: Las aplicaciones generalizadas y versátiles del acero inoxidable dúplex no son tan extensas como las del acero inoxidable austenítico. Por ejemplo, su temperatura de uso debe controlarse por debajo de 250 grados Celsius.

- Menor Ductilidad: Su ductilidad es menor que la del acero inoxidable austenítico, y sus procesos de trabajo en frío y en caliente y sus propiedades de conformado no son tan buenas.

- Fragilidad a temperatura media: existe una zona de fragilidad a temperatura media, lo que requiere un control estricto del tratamiento térmico y los procesos de soldadura para evitar la formación de fases dañinas que podrían comprometer el rendimiento.

En comparación con el acero inoxidable ferrítico, las ventajas del acero inoxidable dúplex incluyen:

- Mejores propiedades mecánicas integrales: Especialmente en términos de ductilidad, es menos sensible a la fragilidad que el acero inoxidable ferrítico.

- Better Localized Corrosion Resistance: Other than stress corrosion resistance, it performs better in other forms of localized corrosion compared to ferritic stainless steel.

- Superior Cold Working and Cold Forming Properties: Far better than ferritic stainless steel.

- Better Welding Performance: Also superior to ferritic stainless steel, often requiring no preheating before welding and no post-weld heat treatment.

- Wider Range of Applications: Its application range is broader compared to ferritic stainless steel.

However, duplex stainless steels disadvantages compared to ferritic stainless steel include:

- Higher Alloy Element Content: This leads to relatively higher prices, whereas ferritic stainless steel generally does not contain nickel.

5. Applications of Duplex Stainless Steel

Duplex stainless steel is a versatile material used in highly corrosive environments and structural engineering materials. Its applications include:

- Papermaking industry

- Chemical and petrochemical industry

- Hydrometallurgy

- Organic acids and caustic alkali media

- Pollution control equipment

- Chemical storage tanks

- Offshore and coastal applications

- Pipeline installations in wineries

- Building structures

6. History of Duplex Stainless Steel

Duplex stainless steel has a history of nearly 80 years, with its microstructure consisting of equal parts ferrite and austenite phases. Early grades were alloys of chromium, nickel, and molybdenum. The first batch of forged duplex stainless steel was produced in Sweden in 1930 and used in sulfuric acid papermaking industries. These steels were high-carbon duplex stainless steels, initially developed to reduce intergranular corrosion issues. In 1930, Finland produced cast duplex stainless steel, and in 1936, France obtained a patent for a steel grade later known as Uranus50. After World War II, AISI329 stainless steel became a mature grade and was widely used in nitric acid equipments heat exchanger pipelines. 3RE60 was one of the first-generation duplex stainless steel grades developed specifically to improve resistance to chloride stress corrosion cracking (SCC). Later, both forged and cast duplex stainless steel grades were used in various processing industries, including containers, heat exchangers, and pumps.

The first-generation duplex stainless steel had good performance but had limitations in the welded state. The heat-affected zone (HAZ) of the weld joint had lower toughness due to excessive ferrite, and its corrosion resistance was significantly lower than that of the base metal. These limitations restricted the application of first-generation duplex stainless steel, typically limited to non-welded applications. The invention of stainless steel refining and argon oxygen decarburization (AOD) process in 1968 made the production of a range of new stainless steel grades possible. One of the many advances brought by AOD was the deliberate addition of nitrogen as an alloying element. Nitrogen alloying of duplex stainless steel made it possible for the toughness and corrosion resistance of the HAZ to be close to that of the base metal in the welded state. As the stability of the austenite phase improved, nitrogen also reduced the rate of harmful intermetallic phase formation.

The second-generation duplex stainless steel features nitrogen alloying. This new commercial progress began in the late 1970s, coinciding with the development of North Sea offshore oil and gas fields and the demand for stainless steel with excellent resistance to chloride ion corrosion, good processing properties, and high strength. 2205 became the main grade of second-generation duplex stainless steel and was widely used in offshore oil platform gas gathering pipelines and processing facilities. Due to the high strength of such steels, allowing for reduced wall thickness and weight on platforms, their application became highly attractive.

Duplex stainless steel has been continuously evolving, with a range of grades containing different corrosion characteristics, depending on their alloy composition. Modern duplex stainless steel can be classified into five types:

- Economical duplex stainless steels without molybdenum, such as 2304;

- Standard duplex stainless steels like 2205, which are the main grades and account for over 80% of duplex steel usage;

- 25Cr duplex stainless steels like Alloy 255, with a PREN value less than 40;

- Super duplex stainless steels (PREN value 40-45), containing 25%-26% Cr, higher molybdenum, and nitrogen content than 25Cr duplex stainless steels, such as 2507;

- Hyper duplex stainless steels, high-alloyed duplex stainless steels with a PREN value exceeding 45.

7. Applications of Duplex Stainless Steel

Flue Gas Desulfurization

In coal-fired power facilities, further reducing SO2 emissions, and flue gas desulfurization (FGD) is a method to achieve low SO2 emissions. Using lime or limestone slurry to "wet scrub" SO2 from flue gas is a mature technology that has been used as a basic method in power plant boiler systems since the 1970s.

Modern FGD units can currently remove up to 90% of SO2 from exhaust gases. Modern FGD units consist of several zones with different temperatures, chloride content, and pH. Due to its lower cost and better corrosion resistance compared to austenitic stainless steel, 2205 stainless steel (S32205) has been used in FGD units in Europe and Asia. Recently, North America has also embraced the use of duplex stainless steel, making it the most popular material choice for FGD absorber tower construction due to its post-weld high strength, excellent corrosion resistance, and high toughness.

Seawater Desalination

Seawater desalination poses one of the most severe tests for materials due to its high chloride content and corrosive process environment. The history of seawater desalination is essentially the history of material development, as clients in the seawater desalination industry seek a balance between meeting corrosion resistance requirements and keeping investments within manageable limits. In early seawater desalination projects, evaporators for multi-stage flash (MSF) and multiple-effect (MED) seawater desalination plants were made of carbon steel. Later, MSF evaporators were generally clad with 316L (EN1.4404) austenitic stainless steel. MED evaporator chambers were initially coated with epoxy resin, later replaced by stainless steel cladding.

The advantage of using duplex stainless steel is its combination of high strength, twice that of traditional austenitic steels, with high corrosion resistance. Therefore, duplex stainless steel evaporators can be made with thinner steel plates and require less material and welding. Other benefits include ease of handling and less overall environmental impact.

Oil and Gas

In the oil and gas industry, duplex steel plays a crucial role in helping to withstand harsh conditions. Duplex stainless steel is mainly used in fluid pipes, process pipeline systems, and equipment such as separators, scrubbers, and pumps. Subsea, these materials are used for downhole production pipelines, fittings, manifolds, flowlines, and pipelines for transporting corrosive oil and gas. Super duplex stainless steel (25% Cr), due to its effective resistance to design stresses, is often used in various aspects such as round bars, forgings, castings, thin plates, thick plates, pipes, and fasteners.

Super duplex steel also has excellent fatigue resistance and good compatibility with other high-alloy stainless steels. Umbilicals are used for wellhead operations control using hydraulic lines and can also be used for chemical injection. Since umbilicals made of steel were introduced to the market, duplex stainless steel has been the most commonly used material. In recent years, with the trend of developing deep-sea oil and gas fields, longer umbilicals are required. Increasing the strength of the material can reduce the weight of umbilicals, allowing for longer lengths.

Biofuels

The biofuels industry, especially ethanol, is an area where the use of duplex steel is growing. 2205 stainless steel has been used in the NExBTL process equipment for biomass oil production in Singapore. In a large-scale biofuel project at the port of Amsterdam, Netherlands, tank manufacturer Oostwouder Tank & Silobouw BV used S32101 for tanks built for Noba Vetveredeling BV. In the expansion project of the Agroetanol ethanol plant on Händelö Island, Sweden, S32101 was also specified for manufacturing containers and pipelines. In many ethanol plant applications, economical duplex steel has been used to replace 300 series austenitic stainless steels.

Food and Beverage

Economical duplex stainless steel has proven its value in the food and beverage industry. This material has been applied in two projects in Spain, one for food storage tanks and the other for wine storage tanks. In the port of Barcelona, Emypro SA constructed food storage tanks entirely using S32101, replacing EN1.4301/1.4307 (304/304L). In Daimiel, southern Spain, a wine storage facility built by Spanish tank manufacturer Martinez Sole for Garcia Carrion used duplex stainless steel for the first time.

Construction Industry

Duplex steel continues to play an important role in bridge construction, where bridges are exposed to corrosion and saline environments while requiring high load-bearing strength. Two recent examples come from Asia, namely the Stonecutters Bridge in Hong Kong and the Double Helix Pedestrian Bridge in Singapore, both using 2205 duplex stainless steel. In 2006, the Stonecutters Bridge used 2000 tons of 2205 duplex steel plates and pipes, with the surface parts constructed by Chinese manufacturers using customized size plates. The plates were polished and shot-blasted to provide optimal reflectivity during both day and night.

Additionally, the Double Helix Pedestrian Bridge used 570 tons of duplex stainless steel. This bridges stunning design incorporates two helical tubular stainless steel sections resembling DNA structures, with the double helical support structures using 2205 duplex steel pipes and plates. Stainless steel surfaces provide nighttime illumination through reflected light, enhancing the design effect.

El techo de acero inoxidable más grande del mundo en el nuevo aeropuerto internacional de Doha en Qatar se construyó utilizando acero inoxidable dúplex económico que contiene molibdeno (S32003). La característica más destacada de la terminal es su techo ondulado, considerado el techo de acero inoxidable más grande del mundo. El techo cubre una superficie de aproximadamente 195.000 metros cuadrados y se utilizaron alrededor de 1.600 toneladas de acero inoxidable dúplex. Se consideraron varios factores al seleccionar el grado de acero inoxidable, siendo el más importante la proximidad del aeropuerto al mar. El techo no sólo debe resistir las altas temperaturas y la humedad del Medio Oriente, sino que también debe resistir la corrosión salina. En comparación con otros grados de acero, el acero inoxidable dúplex tiene ventajas de costos y una buena relación resistencia-peso.

请输入搜索关键字

确定