Tubo de evaporación mejorado | tubería de evaporación mejorada

VIEW MORE+

PRODUCTOS

NOTICIAS

- Diferencia entre Tubo Mejorado de Condensación y de Evaporación

- Entendamos la cabeza de forja

- La estructura de los intercambiadores de calor y las partes principales de la carcasa y el tubo

- Tubo de aleta LL-Foot Vs L-Foot Finned Tube

- ¿Cuál es el tipo de proceso para las bobinas de tubo helicoidal?

- Conocimiento de acero inoxidable dúplex

- Introducir el tubo de caldera ASTM A209/ASME SA209 T1

- Función y aplicación de radiadores de tipo FIN

- ¿Cuáles son los efectos de las zonas afectadas por el calor en los tubos aletas?

- ¿Qué causa las zonas afectadas por el calor?

Tubo de alto flujo | Tubo de alto flujo sinterizado | Tubo de intercambio de calor de alto flujo

Los tubos de alto flujo y los intercambiadores de calor se utilizarán ampliamente en la industria de los intercambiadores de calor. Y el tubo de intercambio de calor de alto flujo se utilizará ampliamente en calderas y intercambiadores de calor industriales.

DESCRIPCIóN

¿Qué es el tubo de alto flujo?

Los tubos de alto flujo son un tipo de tubo intercambiador de calor diseñado para soportar altas tasas de transferencia de calor y altas velocidades de fluido. Estos tubos se utilizan normalmente en aplicaciones donde es necesario transferir grandes cantidades de calor, como en generación de energía, procesamiento petroquímico y sistemas de recuperación de calor residual.

Los tubos de alto flujo se caracterizan por sus altos coeficientes de transferencia de calor, que son la medida de qué tan bien un tubo intercambiador de calor puede transferir calor entre los fluidos que fluyen a través de él. Estos tubos están diseñados con una geometría especial que permite una mayor turbulencia y mezcla de los fluidos, lo que resulta en mayores tasas de transferencia de calor.

Una de las ventajas clave del uso de tubos de alto flujo es su capacidad para manejar altas velocidades de fluido. Esto permite aumentar las tasas de transferencia de calor y mejorar la eficiencia en los sistemas de intercambiadores de calor. Además, los tubos de alto flujo suelen estar diseñados para ser más resistentes a la suciedad y la corrosión, lo que puede reducir los requisitos de mantenimiento y aumentar la vida útil del intercambiador de calor.

Hay una variedad de diferentes tipos de tubos de alto flujo disponibles, cada uno con su propio diseño y aplicación específicos. Algunos tipos comunes incluyen:

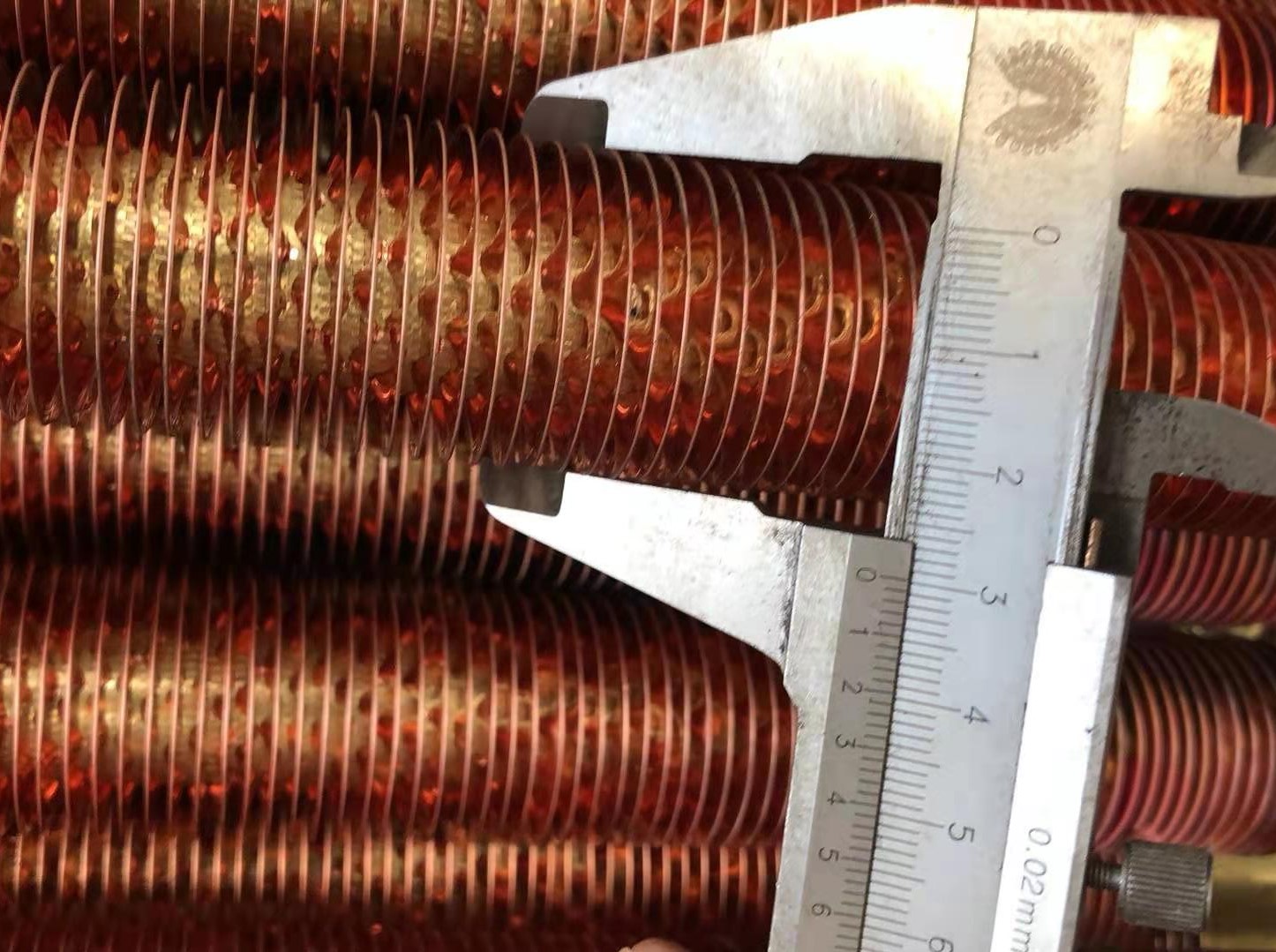

1. Tubos helicoidales de alto flujo: Estos tubos se caracterizan por sus aletas helicoidales, que aumentan la superficie del tubo y mejoran la eficiencia de la transferencia de calor.

2. Tubos con área de superficie mejorada: Estos tubos tienen un área de superficie mejorada debido a su geometría especial, lo que permite una mayor turbulencia y mezcla del fluido.

3. Tubos mejorados internamente: estos tubos tienen una superficie interna mejorada, generalmente mediante el uso de turbuladores u otras geometrías internas que mejoran la mezcla de fluidos y la transferencia de calor.

Overall, high flux tubes are a versatile and effective solution for transferring large amounts of heat in a variety of industrial and commercial applications. Their ability to handle high fluid velocities, resist fouling and corrosion, and provide high heat transfer coefficients make them a reliable and cost-effective choice for many heat exchanger systems.

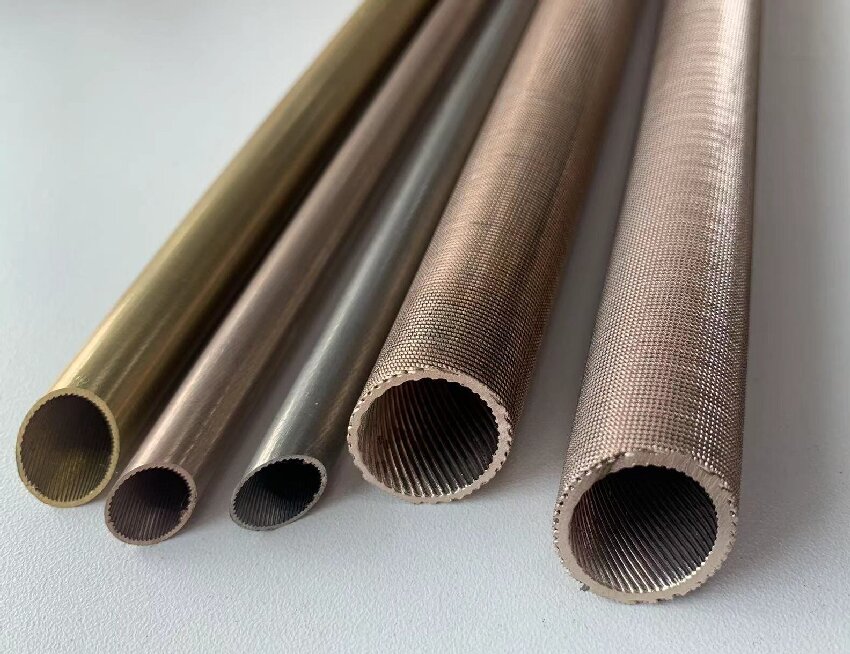

Sintered high flux tube is a highly efficient heat exchange tube with a specific structure on the surface of ordinary heat exchange tube, which is sintered by powder metallurgy method. The concave hole of the surface porous layer is communicated with each other, and the boiling heat transfer can be enhanced obviously, and the heat transfer effect can be increased by more than 20 times. This is so far for heat transfer coefficient of the highest pipe type heat transfer element, especially applicable to alkanes, alkenes, alcohols, such as Freon medium.

Compared with the bare tube, the sintered surface porous tube has the following advantages:

(1) it can significantly enhance the boiling heat, reduce the heat transfer area of about half, and have broad application prospects in the chemical and petrochemical plants such as large ethylene and large aromatics.

(2) in a very small difference in the maintenance of boiling, low taste energy recovery and low temperature boiling heat transfer has a great value, can be used to reduce the temperature of the heating steam.

(3) the critical heat load is more than 50% higher than that of the ordinary pipe.

(4) has good scale inhibition performance.

On the one hand, High flux tube can reduce the steam demand. On the other hand, it can improve the heat transfer capability. In a large heat transfer system, because of the need of small temperature differences, the number of reboilers needed is very large. The use of High flux tube can reduce 3/4 the amount of reboilers, and temperature difference ΔT needed for only 5 ℃. Using High flux tube to replace traditional bare tube we can eliminate heat transfer bottlenecks, meet the need of larger heat transfer load, and significantly increase production. At the same time, while keeping machine efficiency, it can reduce cost by using lower steam pressure.

The case-hardened products are as follows:

Sintered porous coating for the outer surface/low fins for the inner surface, Cannelure for the outer surface/ sintered porous coating for the inner surface, Sawtooth surface for the outer surface/ sintered porous coating for the inner surface, fins for the outer surface/ sintered porous coating for the inner surface.

1.1 Material and size of High flux tube

Material: carbon steel, Aluminum, and so on.

Size: external diameter 15~40mm,length 500~12000 mm

Under normal condition, the middle of High flux tube is strengthened section. Plane ends are smooth, so it is easy to wear and to be expanded. High flux tube can do OEM as customers’ need. Products are packed with wooden boxes.

1.2 Applicable medium of high flux heat exchangers

Ethylene glycol, diethylene glycol, ethylene trichloride, ethane, propylene, ethyl alcohol.

1.3 Applications of high flux heat exchangers

High flux heat exchanger can be used in phase change equipment, such as, carburetor, evaporator, condenser and reboiler, etc. To be specific, such as ethylene carburetor, the overhead condenser and reboiler of ethylene separation device , combination plant of ethylene glycol evaporation and aromatic, main condenser-evaporator of air separation unit. As well as the natural gas liquefaction, cryogenic refrigeration, air separation, and sea water desalination, etc.

1)Oil refining and petrochemical installations

Such as overhead condenser and reboiler of ethylene separation device, ethylene carburetor, catalytic slurry oil evaporator, ethanol evaporator and ethylene glycol evaporator, etc. It can reduce more than 80% heat transfer area, and can also lower refrigerator horsepower. In the long-term operation process, porous surface with enhanced boiling heat transfer is very stable, and no coking or scaling phenomenon has occurred. At the same time it can greatly reduce heat medium consumption, so far as to lower the heat medium temperature.

2)Natural gas purification and separation devices

For example, in the reboiler condensers of cryogenic air separation plant. On the one hand, it can reduce initial cost of evaporation - condensing (cooling) heat exchanger (cut down heat transfer surface); On the other hand, because of the small work temperature difference, it can reduce the power consumption.

3) Sea water desalination and waste heat utilization

1.4 Analysis of high flux heat exchanger economy

To build a set of megaton ethylene equipment, the total investment is above 20 billion RMB commonly, according to history data, heat exchangers cost accounting for about 30% of the total investment , the cost of heat exchangers in each large ethylene project will reach neally 7 billion RMB. But since Chinas energy use efficiency is only 34%, equivalent to that of developed countries 20 years ago, ten percent lower than them now. Developing a higher efficient heat exchanger in smaller temperature difference and less heat transfer surface can be the first step directly related to industrial energy saving development. Using High flux tube and high-efficiency heat exchangers are the most efficient, and also the most economical means to improve the use efficiency of energy.

At present the demand of High flux tube in China is increasing rapidly, in the ethylene industry and other fields, High flux tube and high-efficiency heat exchangers have broad application prospects, thus it has huge potential market demand. There are a lot of high efficient heat transfer tubes in the United States, Japan and Germany, but the technology is still a secret to China, so domestic ethylene industry was forced to use imported High flux tubes.

Los tubos de alto flujo desarrollados por nuestra empresa pueden reducir la superficie de transferencia de calor y el tamaño (alrededor del 80%) de los intercambiadores de calor tradicionales, también pueden reducir la cantidad de intercambiadores de calor en proyectos grandes y reducir las tuberías, controlar la construcción de los cimientos y los costos de aterrizaje del avión. Al reemplazar el haz de tubos de los intercambiadores de calor en la planta existente, se puede volver a utilizar el cabezal, la carcasa, las tuberías, etc. originales.

Tubo de alto flujo|Tubo sinterizado de alto flujo| Intercambiador de calor de tubos de alto flujo | Tubo de intercambio de calor de alto flujo

Products

-

-

Tubos de aleta serpentina | Tubos de aleta de curvatura

VIEW MORE+ -

Tubos de aleta de tensión de borde | Tubos de aleta envuelto

VIEW MORE+

请输入搜索关键字

确定